Aircraft

D Series

The D Series is currently available in two variants, the D7 and D8, with payload capacity up to 15 Kg and 25 Kgs respectively. These are tough, high resilience aircraft with high payload capacity yet retaining high levels of manoeuvrability and agility. They are able to handle harsh environments and operational conditions, include a number of configuration options and can be easily folded for transport. The unusual frame design gives great flexibility in the mounting of payload and sensors and is ideal for applications such as delivery, slung loads, or carrying sensors that need to be separated from the aircraft such as magnetometers.

With the D Series flexibility is the key. Like all our aircraft specification is not fixed and is routinely tailored and adapted to optimise for the particular application, but with the D Series this extends to fundamental change in the aircraft configuration. This aircraft can be built in ‘I’ format, with the core running fore and aft through the aircraft, but it can also be built in ‘H’ format where the ‘front’ of the aircraft is turned 90 degrees giving clearance between the props and a clear view for close quarter operations such as spray cleaning.

Harrier Industrial

This new variant of the Harrier Industrial aircraft is available with 6 and 7 series drive options offering payload capacities to 15 Kgs. The two key features of this variant are its resistance to precipitation and to higher temperature environments. The aircraft has a cover for water resistance plus a second layer of sealing under the cover to prevent any chance of water getting to flight critical systems. Batteries are carried on the side of the aircraft and fitted with easy access custom water proof covering.

For high temperature operations a dual in / out vent and fan system is fitted with a multi path airflow pattern preventing water coming in with the air. Covers are available in white for the high temperature variant, but also in black, or high visibility colours such as orange if required.

Mini 8

The Mini 8 has been designed to meet the needs of those operating in congested areas where flight weight needs to be kept to a minimum, but without a reduction in system redundancy. Normal flight in the case of motor loss can only be achieved with an 8 motor aircraft, a 6 motor aircraft should stay in the air but with compromised yaw control, and a 4 motor quad cannot fly at all in the case of any drive failure. To this end the Mini 8 was designed.

At 3.4 Kgs dry weight and a maximum flight weight of 8 Kgs, this leaves 4.6 Kgs of flight weight to be used for batteries and payload. The balance between the two is up to the operator and will depend on the requirements of the flight and payload. This aircraft is capable of flying for more than 30 mins with no payload, and over 15 mins with a payload of 1.8 Kgs (using a 16Ah 5s lipo @ 1.75 Kgs) giving an AUW of just under 7 Kgs. It can be fitted with retracts or fixed landing gear, anti vibration mounting, includes built in FPV camera if required, and can be folded quickly without tools for transportation. This aircraft is also extremely quiet!

Raven

The Raven is our main work horse heavy lift multi-copter aimed at aerial photography and camera work. Designed for take-off weights up to 25 Kgs the Raven is more than capable of lifting a 10 Kg payload whilst maintaining a high level of speed and manoeuvrability. Made from high grade pure carbon fibre and custom manufactured 6061 grade aluminium, this is an extremely tough, folding aircraft in X8 configuration, designed with ultimate safety in mind, and built to withstand the rigors of real world commercial use.

The Raven was the first aircraft to successfully go through the CAAs CAOSC assessment process, and to this day a Raven still has the highest risk exemption ever granted in the UK. It is used by many of the top movie industry flying camera companies both in the UK and abroad, and a 12 motor variant was the only multi-copter to be allowed to fly at the Rio Olympics 2016 with three aircraft carrying out more than 350 flights over the two weeks of the games. A number of variants of the Raven have been produced, and as with all our aircraft customised versions to meet specific criteria are available if required.

Black Widow

The Black Widow is one of our most popular designs and is ideal for aerial photography, structural inspection, surveying, and other medium lift tasks where high levels of reliability and a clear sensor view are important. The co axial X8 configuration gives good performance in wind, and plenty of lift for carrying medium to heavy loads, whilst also offering very good redundancy against failure. The frame is tough and solid, and includes our tool-less quick fold mechanism for ease of transportation and storage. A well proven anti vibration system and standard payload mounting rails are available, as well as the option for wide spaced retractable landing gear giving plenty of room for a centrally mounted gimbal.

This is a fast and highly manoeuvrable aircraft which offers great stability and good resistance to wind. The use of Z arms gives great 360 degree view for the camera without getting propellers in the shot, ideal for both aerial photography and structural inspection where a clear all round view from the camera is vital.

The Black Widow is now available in both X8 and Hex configurations. It can supplied as a frame for the self-builder or as a ready to fly aircraft. As with all our airframes the Black Widow can be adapted or customised as appropriate for a range of applications and requirements.

Payload Development

As the UAV industry continues to expand and an increasing range of applications are considered, there is a growing need for functional hardware to make these requirements a reality. With our in house design and manufacturing facilities we are able to offer this service alongside our custom aircraft development.

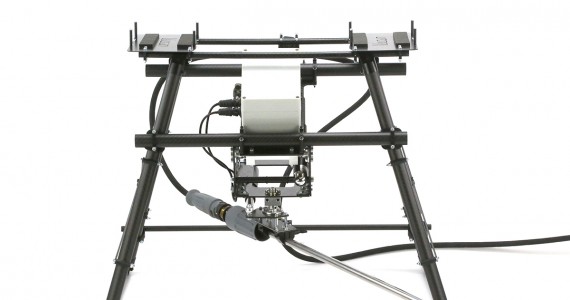

Shown here (right) is the Vulcan UAV smart winch developed by us for delivery of light payloads to areas where landing is not possible (such as the top of wind turbines), or for the placing of equipment or sensors in hard to reach or no access locations (with the addition of our remotely operated dropping hook – not shown here). The smart winch is integrated into one of our removable quick release landing gear systems for quick swapping of different payloads for different functions.

Shown left is a custom remotely operated robotic spray system designed for use in harsh environments. The spray arm is supplied with water from the ground using a high pressure industrial pressure washer, with the water being pumped up to a maximum height of around 200 feet (subject to the choice of pump). The operator can move the sprayer arm in two axes remotely and see where it is pointing from an on board camera. There are three control modes as well as well as automated repetitive motion options for ease of operation.